RoHS Compliant and Advanced PCB Manufacturing for Automotive Medical and Telecommunications Industries

About Suntek Group:

Suntek is a contract supplier in EMS field with one-stop solution for FCB/FPC assembly,Cable assembly and Box-build assembly.

Suntek Electronics Co., Ltd,as the major facility, located in Hunan Prov,China;

BLSuntek Electronics Co., Ltd,as the new facility, located in Kandal Prov,Cambodia.

With ISO9001:2015,ISO13485:2016,IATF 16949:2016 and UL E476377 certified,We deliver qualified products with competitive price to clients all over the world.

With your Gerber file and BOM,we can make it into a real product.

With your physical sample,we can provide the reverse-engineering service to help you copy this product.

With your ideas,we can provide the joint-design service to help you build this product.

Overview:

In the most demanding sectors—where a single component failure can have significant consequences—standard printed circuit boards (PCBs) are not enough. Our advanced PCB manufacturing service is specifically engineered to meet and exceed the rigorous standards of the Automotive, Medical, and Telecommunications industries. We don't just build circuits; we build the foundation for innovation, safety, and global connectivity.

Every board we produce is 100% RoHS Compliant, ensuring environmental responsibility without sacrificing performance. We integrate the latest technological advancements to deliver PCBs that offer superior durability, signal integrity, and long-term reliability.

EMS Advantages:

1) Strict product liability, taking IPC-A-610 standard

2) All teams can speak fluent English

3) PDCA management tool

4) 100% E-test,100% visual inspection, including IQC, IPQC, FQC, OQC

5) 100% AOI inspection, including X-ray, 3D microscope and ICT

6) High-voltage test,impedance control test

7) ISO9001,ISO13485,IATF16949 and UL certified

8) No minimum order quantity

9) Focus on low to medium volume production

10) Quick and on-time delivery

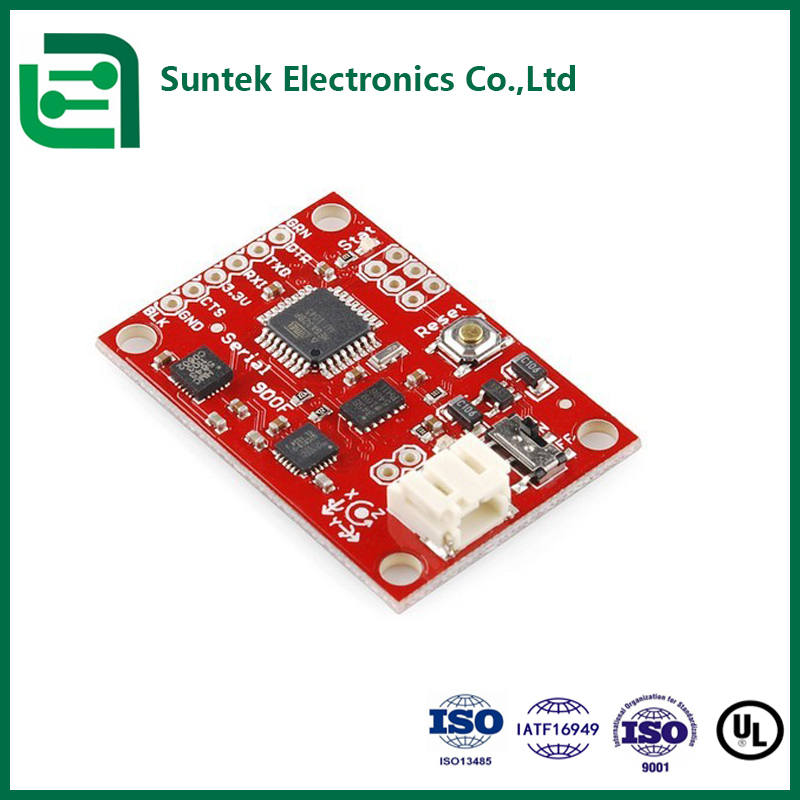

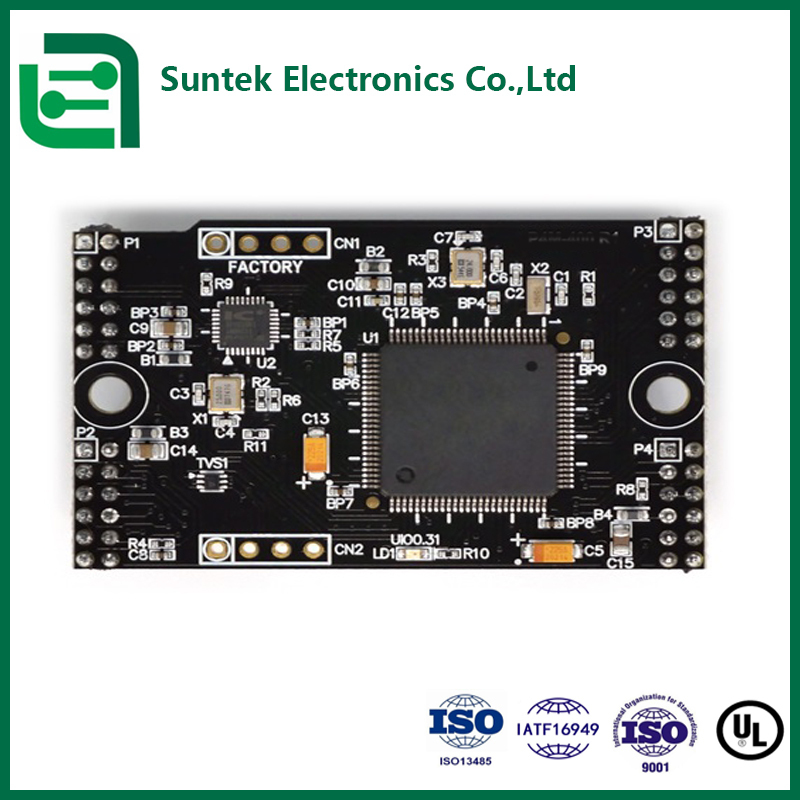

Some PCBA Pictures:

PCB Assembly Capability:

| Item |

Parameter |

| Board Type: |

Rigid PCB, Flexible PCB, metal core PCB,Rigid-Flex PCB |

| Board Shape: |

Rectangular, Circular and any irregular Shapes |

| Max Size: |

400mm * 1200mm |

| Min Package: |

0201 |

| Fine Pitch Parts: |

0.25mm |

| BGA Package: |

Acceptable |

| DIP Capacity: |

DIP lines and AI assembly line |

| Parts Sourcing: |

All by Suntek or partical consigned by customer |

| Parts Package: |

Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk |

| Testing: |

Visual inspection, AOI, X-RAY,Functional Testing |

| Types of Solder: |

Lead or Lea-free (RoHS Compliant) assembly |

| Assembly Option: |

Surface mount (SMT), Through-hole (DIP), Mixed technology

(SMT & Thru-hole) |

| Stencils: |

Laser cut stainless steel stencils,step-down stencil |

| File Formats: |

Bill of Materials,PCB(Gerber Files),Pick-N-Place File (XYRS) |

| Quality Grade: |

IPC-A-610 Class 2/Class 3 |

Application:

Key Features & Benefits by Industry:

1. Stringent RoHS Compliance & Environmental Responsibility

Feature: Full adherence to the Restriction of Hazardous Substances (RoHS) Directive. We use only certified lead-free solders, substrates, and finishes.

Benefit: Guarantees your products can be sold globally, reduces environmental impact, aligns with corporate sustainability goals, and ensures safe manufacturing and end-use.

2. Advanced Capabilities for Automotive Reliability

Feature: PCBs built to withstand extreme conditions, compliant with IATF 16949 standard. Capabilities include:

High-TG Materials: (e.g., FR-4 TG170, TG180) for superior thermal resilience against engine heat.

Heavy Copper Boards: Up to 20oz for high-power applications (e.g., power controllers, LED drivers).

Robust Finishes: ENIG (Electroless Nickel Immersion Gold) and HASL Lead-Free for excellent corrosion resistance and solderability.

Enhanced Testing: Extensive Automated Optical Inspection (AOI) and In-Circuit Testing (ICT) to ensure zero-defect performance.

Benefit: Unmatched durability for under-the-hood applications, infotainment systems, ADAS sensors, and power management units, ensuring passenger safety and vehicle longevity.

3. Uncompromising Quality for Medical Devices

Feature: Manufactured in certified ISO 13485 quality management system.

We specialize in:

High-Density Interconnect (HDI): Micro-vias and fine-pitch components for miniaturized, high-performance devices (e.g., implants, portable monitors).

Biocompatible Materials: Selection of substrates and laminates suitable for devices that contact the human body.

Rigorous Traceability: Full lot-to-lot and panel-level traceability for complete accountability.

High-Frequency Materials: For precise imaging and diagnostic equipment (e.g., MRI, CT scanners).

Benefit: Critical for patient safety, device efficacy, and achieving fast regulatory approval (FDA, CE Marking) for life-saving medical equipment.

4. High-Speed/High-Frequency Performance for Telecommunications

Feature: Expertise in RF and Microwave PCB design for 5G infrastructure, network hardware, and satellite communications.

Low-Loss Materials: Rogers, Taconics, and PTFE-based laminates (e.g., ISOLA, Panasonic) to minimize signal loss at high frequencies.

Impedance Control: Tight tolerance controls (±5% or better) for critical signal paths.

EMI/EMC Shielding: Techniques like buried capacitance and shielded vias to prevent electromagnetic interference.

Complex Multilayer Boards: Expertise in manufacturing 20+ layer boards with precise layer alignment.

Benefit: Enables faster data transmission rates, reduces latency, and ensures stable, clear signal integrity for next-generation communication networks.

With ISO9001:2015,ISO13485:2016,IATF 16949:2016 and UL E476377 certified,

Why Choose Suntek?

As an experienced and reliable manufacturer,Suntek provides one stop service, including PCB manufacturing and PCB assembly for all customers in the global who has diversity requirements in their projects with our strong teams. It can help customers to save their time and money to complete their products with the highest quality but favorable price in only one place.

Instant Quote

You will get our instant quote within 24 hours to 48 hours and positive feedback for all your specifications about your projects.

Strong Team

Our professional and experienced experts and engineers will give you the technical support from PCB design to the turnkey PCB assembly all the times. all questions can be answered in the whole process without time delay.

Automatic Equipment

All advanced automatic equipment helps us to improve working efficiency and cost efficiency. we will do everything possible to offer you the boards with the highest quality but competitive price on time.

After Sales Service

We will track all orders for all customers throughout. our customer service representatives will be online available to give you the instant update in every process.

Our supports:

We ensure cost transparency, BOM cost breakdown sharing;

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

EMS PCB Quality Control:

FAQ:

Q1: What files do you use in PCB fabrication?

A1: Gerber, PCB. Auto CAD

Q2: How do you make sure the quality?

A2: Our Product is all 100% E-tested .PCB Assembly are with 100% AOI,ICT,FT and Visual checking,100% X-ray for BGA.

Q3: Can we visit your company?

A3: Of course,Welcome to visit our company, Suntek located in Xingsha Industrial Park, Changsha,Hunan province, China.

Q4: What is the lead time?

A4: It takes 3-5 working days for sample, 7-10 working days for batch production based on files and quantity. It takes 15-20 working days for PCB assembly.

Q5: Will you keep our information and files secret?

A5: Sure,It is our basic principle to keep business secrets to protect our customers' designs.NDA can be signed at any time.

Q6. How to work with you?

A6: -Email and send us the PCB layout file, BOM list

- We will provide reply confirmation within 12 hours and reply to the offer within 3-5 days.

- Waiting for your company to confirm the price, order and payment terms.

- We will proceed the order.

We have advanced manufacturing equipments and technology,professional engineer team,purchasing team,quality team and management team to guarantee

the high quality products and on time delivery.Our products are widely used in industrial control,auto,telecommunications,medical equipment,consumer electronics and etc.

PCBA Equipments:

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!